Tuesday, 18 November 2008

Lincoln Imps and Pressure Beds

Last week found me travelling around the North of England with Bernd Mahnke of Care Concept Mahnke, showing an innovative pressure mattress system to UK companies supplying the NHS intensive care wards and nursing homes. Despite the highly price competitive market, we had interest and friendly advice on adapting to the UK market (see report "Avoiding sore points in bed" at http://www.miltoncontact.co.uk/care-concept-mahnke).

Crucially, we found ourselves with a couple of hours to spare and visited the Cathedral city of Lincoln, providing a unique opportunity to also gain some insight to british culture & traditions on a business trip, rather than just looking at the open road from appointment to appointment!

I hadn't realised that Lincoln Castle is the repository of one of three remaining copies of the Magna Carta, which we were able to enjoy with detailed friendly information from the helpful staff on hand. Not only was this document the germ of democracy, it also started off a fair(er) justice system where even royalty could be held to account, with the initiation of the Assizes that migrated around the counties dispensing justice. We were fortunate that the continuation of this 800 year old tradition, the Crown Court, was in action at the time of our visit, with the duty constable and a Barrister taking his coffee break giving us a real life glimpse of a living law in action.

A more sober reality was the visit to the last Victorian separation chapel where prisoners used to be taken hooded for communion and the only opportunity to use their voices was by singing. The inner fort, whose walls had been reduced in height by half by Cromwell, caused us to reflect over the somber small gravestones of the hanged.

The law used to be dispensed and taxes collected at the castle by the Sherrif of Lincoln. We were fortunate to encounter him in his Victorian Dress suit and sword in the nearby cathedral, at the end of a commemorative service for North England schools, and exchange a few words.

The Cathedral itself was a Norman delight and a chance encounter with other visitors had us hunting for the Lincoln imp, an emblem of the city and its football club since an enterprising jeweller made it into Christmas gifts at the end of the 19th Century. The story goes, that the devil sent out his imps to cause mayhem and one entered the cathedral. Having caused chaos it settled, cross-legged on a pillar to grin over its handiwork. However, the Cathedral Angels turned him to stone, and there he remains to this day!

English food has a poor reputation abroad and it was therefore also a great pleasure (and culinary delight) to find two pubs on our trip with excellent food in contrasting locations - The White Houses Inn in Retford where we enjoyed partridge and pheasant, and the Wickham Arms in Cleckheaton, where we had a roast with Yorkshire Pudding.

Such an apparent diversion on a business trip is actually very useful as it helps a visitor gain a better understanding of the British culture and mentality, often through the chance encounters as well as the business ones.

Bernd was able to return to Luton for his flight home with a raft of memories and positive business contacts from a hectic but eventful trip!

Tuesday, 14 October 2008

Internationally - the importance of local contacts

Being a small company has its advantages, such as flexibility and the ability to adapt to new opportunities as they arise. The disadvantage is that, if you try to do everything yourself, you can rapidly find yourself doing everything. The solution is partnership with like minded companies having complementary skills.

I already work closely with Europartnerships on international projects assisting visitors to the UK, bringing in Virtual Advantage to help with the volume of work in the UK and Come Across, based in Berlin for local German access.

Christa Friedrichs of Expand International is a welcome new partner to our collaborations! With her assistance, I am able to provide a local contact and personal face to Leipzig companies in a current project that we are working on. Telecommunications and internet allow us to communicate and ensure that the client companies are well looked after.

Christa is based in Leipzig, with three or more years experience of international assistance to German companies. With her background in Chemical engineering, I have the additional pleasure of knowing that I can talk science if need be!

I already work closely with Europartnerships on international projects assisting visitors to the UK, bringing in Virtual Advantage to help with the volume of work in the UK and Come Across, based in Berlin for local German access.

Christa Friedrichs of Expand International is a welcome new partner to our collaborations! With her assistance, I am able to provide a local contact and personal face to Leipzig companies in a current project that we are working on. Telecommunications and internet allow us to communicate and ensure that the client companies are well looked after.

Christa is based in Leipzig, with three or more years experience of international assistance to German companies. With her background in Chemical engineering, I have the additional pleasure of knowing that I can talk science if need be!

Monday, 8 September 2008

The Challenge of Rain

This past week has seen torrential downpours across England and I took this as a challenge photographically, how do I photograph rain?

Therefore, much to the amusement of neighbours, I dashed outside as showers began; my camera protected under a large umbrella as the rain ran down the back of my mac to soak my trousers and feet.

Ripples in growing puddles afforded the first subject. As the puddles grew and the showers intensified, the rain whipped the surfaces and the bouncing drops hinted at where to go next - capturing raindrops themselves on camera.

Despite shutter speeds of 1/1000s or less, the rain fell too fast and it was only the results of hitting water or a surface that seemed accessible. Photographing an expanse of water resulted in a repetitive and confusing image, so the telephoto lens was used to concentrate on small patches of water.

It was only then that I learnt that whilst there was enough rain to soak me in a normal shower, the likelihood of capturing a raindrop as it hit water or shortly afterwards was actually relatively small.

For once, I welcomed a torrential downpour and photographed innumerable pictures of a puddle close up with a fast shutter speed and high ISO setting (1/1000s; ISO 1600. Screening and cropping of the resultant pictures ended up with the selection of a handful as seen in the slide show above. Depending on the depth of the puddle you could get a crater with droplets emitted at its border or a single drop or string of drops bouncing back out of the centre.

A neighbour's car gave an alternative surface to show the impact of drops on the film of water covering the bonnet. The shiny surface gave an interesting distorted reflection of flowers behind the car when the focus was adjusted.

The departing rain left an enormous puddle which mirrored the house at the end of the road. By rotating the image 180 degrees, the house was reflected accurately but appeared set in a strange environment.

The rain that had previously kept me indoors was transformed into a strange and beautiful subject when taken as a photographic challenge.

Rain can also be destructive; please also spare a thought for those made homeless both in the UK by the same rain and the people of the Caribbean affected by the tropical storms and hurricanes Hannah and Ike. If, like me, you would like to help them, visit the Red Cross hurricane disaster appeal page and make a donation.

Wednesday, 27 August 2008

Dragons over Fen Drayton Lakes

Click on the slideshow for full images in Picasa online album

Early afternoon on a blustery day, the sun shines through ragged clouds hurrying across the sky over the RSPB reserve at Fen Drayton Lakes. Approaching the lakes, first one lonely marauder patrols the skies, then more appear till, on a small sunlit bridge, the Stansted of Dragonflies appears. Basking on the wooden railings are Common Darters in varying colours from greeny browns to reds, whilst thin flashes of blue indicate their relatives, the Damselflies.

This was a good opportunity for macro-photography with a 80 - 300mm equivalent telephoto lens and a 25mm spacer. The main challenge was focal depth which was countered with a reduced aperture as the light still permitted a 1/200s exposure.

Damselflies fold their wings together over and along the body; Dragonflies spread them out horizontally.One of the key indicators for individual species is the wing venation, with small triangles and colour patches on fore and hind wings being of particular importance.

The walk extended over three miles and it was with reluctance that I dragged myself away from a second session with the living helicopters at the end of the afternoon.

Tuesday, 26 August 2008

Egyptian Letters from the British Museum

click on the slideshow to get to Picasa album that can be viewed full screen

We are quite priveleged to have institutions such as the British museum, where you can not only enjoy the exhibits but also photograph them. It was with a sense of anticipation that I therefore entered the imposing museum in London. I had no preconceptions subject wise and soon discovered the first delight at the inner Queen Elizabeth II Great Court, designed by Foster & Partners.

The giant quartzite 1400BC head of Amenhotep III in the courtyard led to the lower Eqyptian Gallery. Low light was the main challenge without a tripod. Using a telephoto lens (80mm-300mm equivalent) almost exclusively led to appreciation of a few individual objects, from the limestone Horus head to the giant scarab.

With a lifelong interest in Calligraphy, however, I was drawn to the hieroglyphs in stone and later, on wood and papyrus in the upper galleries. the added challenge to low light was reflections on the protective glass casings or frames on the latter exhibits. Again, rather than necessarily photograph entire subjects, I concentrated on elements or details.

Three trends immediately became apparent; the existence of parallel scripts (hieroglyphics & hieratic) right from 3000BC, the effect of different substrates and media and the considerable variation in quality and style.

Indeed the biggest surprise was that rather than the hieroglyphics preceding the invention of a more abstract writing, the hieratic script used for legal and priestly documents was already developed and in use at the start of the first dynasty 3000 yrs ago. Hieroglyphs existed in parallel and were mainly used in monuments and religious documents, where there was also a cursive hieroglyph script.

Writing in stone using a chisel or scraper versus painting or writing on a surface with ink also impacted on the representation of the hieroglyphs. Glyphs could be carved into the stone or made to emerge in bas-relief. Soft stone like limestone presented different challenges to working on granite. On papyrus or wood, the thickness of the pigment, the nature of the brush or pen allowed a wide variety of strokes that could be millimeter precise or flow more cursively with the hand in the act of writing.

Egyptian scribes and artists worked as part of a team and there was a trememendous millenial tradition of utilising consistent styles to demonstrate continuity and timelessness. And yet a closer look reveals tremendous variation in skill, style and attention to detail! One set of carvings exude sophistication and quality, whilst another is much coarser. Composition and style might be set but the slight changes in the proportions and spacing of glyphs or letters and the subtle flow of the strokes by different scribes are recogniseable.

New knowledge impacts on perception and a return visit to the Museum would now result in a different set of photos, perhaps following up on some of the themes discovered.

Mind you, there are also other ancient scripts contemporary with the Egyptions to pursue such as the Cuneiform and Meroitic, not to mention the derivative Demotic.

References:

1. Wikipedia gives an excellent introduction to all the scripts mentioned here.

2. Cyril Aldred " The Egyptians" 3rd edition 1998, ISBN 0500280363, pp 204-207 gives an insight to the artists and scribes and how they worked, including 4h morning shift, lunch break 4h afternoon shift, skyving optional and servants to do the houseowrk.

3. Denys A Stocks "Experiments in Egyptian Archaeology" 2008, ISBN 0415306647 p96, available online on Google books, describes how flint tools might have been used to cut hieroglyphs.

Sunday, 10 August 2008

A useful addition to the tools of a peripatetic business-person

Do you find yourself traveling more and wanting to do work en route whilst equally wishing to minimize the amount of weight you have to carry around without excessive expenditure?

I finally reacted to finding myself in this situation by purchasing an ASUS 4G, with a Linux based operating system, as a minimal laptop. I've been pleasantly surprised at the versatility, but how well would it hold against the critical review by a visiting teenager?

Richard Krahnstöver generously offered to give me his considered opinion. Here are his pros and cons;

Cons

- Not for gaming, mainly office applications

- Screen too small for precision work and design (although can be attached to larger screen)

- Problems with WAP enablement (wpa, solutions exist but novice would have difficulty knowing how to sort them out)

- Not so easy for the novice to download and install other linux based software.

Pros

- View it as a specialised tool

- Good for office applications

- Portability – hard-back book size and less than 1kg in weight

- Communication via Skype or Messenger

- Acess to media sites such as Picasa and YouTube.

- Good enough to present final work

- An extra-dimensional Mobile

- Good for information gathering on the web due to wireless and cabled connections

- speed of use

- Linux is advantageous – simple menu structure, restricted set of options increases efficiency

Richard considered the Asus a good tool for office related work and even giving presentations.

I might add that the communication elements such as chat software, VOIP via Skype and accessing online social networking sites were readily used by all my younger visitors and family over the Summer break. The slower processor and the limited solid hard drive space seemed of little consequence as people adapted effortlessly to the capabilities of the machine.

I personally found that in addition to the expected office applications, the Asus in conjunction with Picasa was excellent for downloading and quick screening of the innumerable photos i take professionally and for pleasure.

One unexpected benefit of the compact nature of the Asus for someone approaching a more mature age was, that I could work on it on my lap comfortably using my bifocals, whereas i needed separate spectacles for the large screen office PC!

If you want something more than a mobile, with a reasonable keyboard but without the weight and all singing all dancing functionality of a high range lap-top, Then seriously consider an Asus 4G or similar familiy member.

This article was written and uploaded to the internet using the ASUS 4G, without any great difficulty.

Tuesday, 8 July 2008

Talking technology for small businesses

One of the common elements that frustrated us both was the lack of user friendliness in many applications. Even updating and managing your website can become over complicated.

Ironically, in this day and age of service variety and options, you sometimes just wish there was a simple shortcut to allow you to undertake the routine tasks; leaving you the option of looking at other features when you have the time and inclination.

Two positives from our experience are Skype - very easy to set up and use and the telephone assistance for BT connect business users.

Richard and I both enjoy collaborating and using collaborative tools, from google docs to Microsoft live, utilising Skype conferencing or windows live messenger on the way! Collaboration is an excellent way for small businesses to extend the range of services and skills that they can provide.

Monday, 7 July 2008

Blooming Success at Open Studios

Visiting Heather Maunders, artist, in Little Downham today, we talked about the unexpected preferences of the public for pictures that an artist might produce.

I remember exhibiting in Cambridge Open Studios for two years running(I'm still a member) and thoroughly enjoying people dropping by to talk about my photography and artwork. Heather's exhibiting for the first time this year with her large portfolio of artwork inspired by both flora and fauna.

One would have though that in this current age, the trend would be towards modernistic abstract painting, however, Heather was pleasantly surprised to find that it was her detailed and accurate studies of flowers that resonated with her visitors.

By often concentrating on close up detail, heathers pictures reveal the inner beauty of the flower, created by the complexity of the petals, anthers and the interplay of light, colour and shade.

By often concentrating on close up detail, heathers pictures reveal the inner beauty of the flower, created by the complexity of the petals, anthers and the interplay of light, colour and shade.The other problem we were discussing was the difficulty on obtaining good, high quality prints of artwork as a cost effective alternative to the originals. Heather has gone the whole hog and has purchased the equipment to control the whole process herself from painting, scanning to printing.

If you can, try to attend Cambridge Open Studios on the weekends during July, and of course make a particular effort to see Heathers pictures. If you cannot, an equally enjoyable alternative is to visit her website at http://www.heathermaunders.com/. And next year, I think I'll exhibit again too!

Thursday, 19 June 2008

Men about Town with Pyjamas

My colleagues from Jado understood English but wished to ensure that they had the best English communication with their UK partners, I was to be that communicator.

Our initial discussions culminated in the key phrase encapsulating their business “Jado; Quality, Flexibility and Reliability in delivering stylish nightwear to your customers”. By early afternoon, I was also able to deliver a 10 minute presentation without notes using a mnemonic that included amongst others, Cary Grant in a Mercedes wearing oversized pyjamas!

Day 1 included a trip to Warwick, day 2 was spent in London and taxed the physical stamina of the Jado delegates. Selected items from their current Autumn and Spring collections (from their in-house designer) filled two large suitcases that accompanied us to all our appointments. If it is one thing we learnt about the Underground system in London, it’s that there are a lot of stairs and not enough escalators and lifts.

Our hosts at each of the meetings made up for the tribulations with their courteous interest and time given; even where the collection was not relevant to one particular client, we benefitted from discussions on potential alternative markets and strategies.

As always, business trips detract too much from actually seeing the sights and Roland and Jörk promised to come back on their next trip to London with extra time on their hands to see more of the city itself. By stealing some time before meeting them and a late night in Westminster, I was able to at least give them a vicarious glance at one or two items missed (see photos at http://picasaweb.google.co.uk/miltoncontact/AccompanyingJadoToLondon )

Though hectic, hot and at times intense, we made a good team and came away on a positive high from the two days with my broad overviews in English being supported by the detailed expertise of the others and of course by the high quality items on display.

If you want to know more about Jado, please do visit their site at http://www.jado-herrenwaesche.de/jado/2008hw/fs_1_e.htm .

Milton Contact Ltd; providing assistance to overseas companies wishing to explore the UK market, through market research, finding contacts and accompanied visits.

Wednesday, 7 May 2008

Three factors ensuring success for local PCB manufacturer

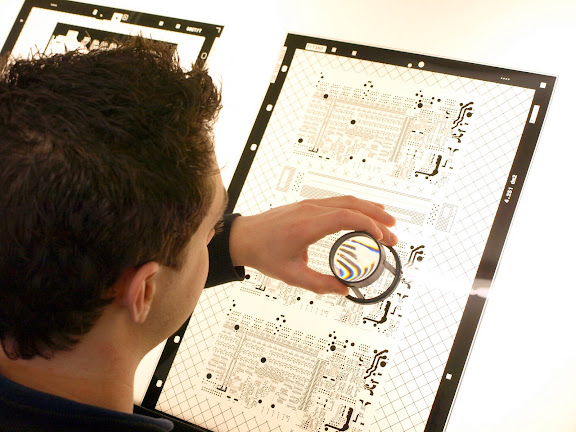

St Ives, Cambridgeshire, is probably more familiar as a market town with a distinctive bridge and waterfront on the Great Ouse. Gennaro Coppolaro of Polar Communications had invited me there to do a business photo shoot at Anglia Circuits Limited, a printed circuit board (PCB) manufacturer located on one of the business parks of the town, as part of their current website construction. I discovered a fascinating and thriving business and identified the three factors that ensure it's continued success; finding a niche, setting high quality standards and good relationship marketing.

Background

Open up any of the key electronic components that we take for granted during our business and private lives, from mobile phones, Blackberrys to PCS, cars and calculators, and you will find a printed circuit board (PCB). The PCB is the board with all the electrical connections and tracks; the transistors, processors and other electronic components are all added at a later stage; imagine the PCB as a railway network and all the attachments as the stations, signalling and trains.

Because of their ubiquity, there is a major and highly competitive market nationally and worldwide for PCB manufacture. There are at least 97 manufacturers in the UK, the US has more than 3800 and there are 300 plus large multimillion PCB international businesses in a market expected to grow from $50bn in 2007 to $76bn in 2012. As with any manufacturing sector, Asia is becoming a major powerhouse in PCB manufacturing with a concomitant price pressure and a decline in US and European manufacturing. Surviving and even growing as a PCB manufacturer in the UK is therefore by no means a mean feat.

Looking at the actual methodology, it comes as a surprise to find that the concept of a printed circuit board was already apparent to Edison when he responded to the Sprague Electrical Company request on how to "draw" conductive traces on paper. Early methods were "additive", in that they suggested different ways of adding a circuit to a substrate. In 1913, Arthur Berry filed for a patent for etching away metal covered in a pattern of resistant material to leave defined tracts, forming the basis for so called "subtractive" methods. These evolved, invention by invention, until by the end of World War II in the UK, the founding father of modern PCBs, Paul Eisler, was electrodepositing copper foil on planar substrates and etching it away with ferric chloride to leave circuits .

By 1948, the US had released the technology for general application and the technology has expanded from there. Nowadays, PCB manufacturers can purchase boards with a surface bonded copper sheet layer, itself covered in a photoresist layer, ready for PCB production.

Initially all added components were fixed to PCBs by wires going through the board (Through-hole mounting), a method still used for larger components; with the 1960s came the surface mounting with soldering (Surface mount).

Even with innovations, this is a well established technology, with an apparently straightforward manufacturing process, that lends itself to mass production of low cost units. So how can a UK PCB company remain competitive?

Cue my visit to Anglia Circuits Limited, camera in hand, with a brief to photograph staff, to capture the key stages in the PCB work-flow at the company and to photograph examples from the wide range of PCBs produced to date.

The visit

After a warm welcome by Matthew Kember, Owner/Manager of Anglia Circuits Limited, and an introduction to the other team members, the staff photos came first. Whilst most people do not like their photos being taken, I was treated courteously and gained an impression of a friendly, positive, dedicated team and a well run company from the conversations I had. This impression was reinforced as I toured the company to photograph the key stages in PCB manufacturing at Anglia Circuits Limited and met more staff on the shop floor.

Factor 1. Targeting a niche market

Anglia Circuits Limited specialises in short production runs of tens to hundreds of PCB made to order for a clients specialist requirements. This distinguishes them on the one hand from the other specialists who make unique one off PCBs, which are used in prototype testing or R&D, and from the mass market that produces thousands to millions of a particular PCB design. This targeting of a niche market for short production run PCBs is the first factor contributing to the company's success.

Factor 2. Setting high quality standards

Quality control was a consistent theme when I began my photographic tour of Anglia Circuits Limited, (reproduced in a truncated version as a photo album at http://picasaweb.google.com/miltoncontact/PCBManufacturingAtAngliaCircuits to complement this article and as thumbnail links in this document). A very simplified description of the PCB production nevertheless gives a good impression of the checks at every stage.

Circuit plans arrive from clients and are screened by resident expert before being printed as acetate masks (slide 02) for the photo-lithographic etching process. A completed PCB may consist of up to 14 separate layers of circuits fused in a completed board; each layer requires its own design. The acetates are then visually inspected (slide 03) before being passed on for alignment and mounting on the PCB/Copper/Photoresist blank board (slide 04). Once exposed, (slide 05), the unmasked resist is removed, exposing bare copper (slide 06) which is etched away to leave the remaining tracks under their layer of protective tin resist (slide 07). The tin layer is itself removed, revealing the copper circuits beneath (slide 08). At this point, each layer produced is checked by a sophisticated computer with image analysis software: Any highlighted potential defects are assessed by the human operator, who can remedy minor errors (slide 09).

The individual circuit layers are then accurately assembled by hand (slide 10) and heat bonded. The multi-layer PCB is precision drilled to permit through board mounting of future components (slide 11) and the holes themselves are carbon coated and plated to ensure electrical conduction where required between layers (slide 12). The drilled boards need to go through a final stage of photolithography to produce the surface circuits of the stack (repeat of slides 03 - 09).

The boards are sprayed with a protective coat that imparts the characteristic green (or any other) colour for a PCB (slide 13). Yet another photolithographic process is used to expose the solder points on the board (slide 14). These points are treated to impart the final silver or gold finish (slide 15).

The final stages are to print the text descriptions on the board (slides 16 and 17) and cut out the individual PCBs from the larger multi-unit panels (slide 18). The completed PCBs are then inspected manually for accuracy and surface defects (slide 19) before testing every individual circuit on each PCB using a state of the art EMMA flying probe (slide 20).

So you can see, even from this simplified description, that the continual quality control throughout manufacture ensures that the despatched product (slide 21) matches the client’s requirements by providing a high quality, tested and reliable PCBs.

Factor 3. Good relationship marketing

Matthew Kember told me that he'd asked clients what was important for them when considering Anglia Circuits Limited as a PCB supplier in a competitive market. He was surprised to hear that it was in part because the company was a family owned business established since 1968. (In fact, Anglia Circuits Limited claim to be the oldest, established PCB firm in the UK!) The company has acquired a reputation for quality, reliability and flexibility that ensured clients returned to provide more business. The positive atmosphere, ethos and practice existing within the organisation that I had noticed during my visit (and confirmed subsequently) had also been applied externally to foster good relations with clients.

The continued nurturing of clients and meeting their needs with a quality service has meant that 90% of the business derives from existing and established customers who return year after year.

Conclusion

By targeting a particular niche in the market for PCBs - low volume production, Anglia Circuits Limited is able to concentrate on the provision of a high quality controlled product to discerning clients who, through good relationship marketing, have formed a loyal client base providing 90% of the business. The result is that Anglia Circuits Limited was able to expand by 25% two years ago, acquire more state of the art equipment to complement and improve their existing production lines this year. They are considering another expansion phase in the near future; All this in a highly competitive and saturated World market.

You can contact Matthew Kember for more information about Anglia Circuits Limited and their PCB manufacturing on 01480 467770.

Author: Dr Chris Thomas, Director Milton Contact Limited

Creating effective communication in your team, your business or internationally, through interpersonal skills, text and images.

A PDF version of this document with 21 images is available at http://www.miltoncontact.com/news01/PCB-manufacturer.pdf

Background

Open up any of the key electronic components that we take for granted during our business and private lives, from mobile phones, Blackberrys to PCS, cars and calculators, and you will find a printed circuit board (PCB). The PCB is the board with all the electrical connections and tracks; the transistors, processors and other electronic components are all added at a later stage; imagine the PCB as a railway network and all the attachments as the stations, signalling and trains.

Because of their ubiquity, there is a major and highly competitive market nationally and worldwide for PCB manufacture. There are at least 97 manufacturers in the UK, the US has more than 3800 and there are 300 plus large multimillion PCB international businesses in a market expected to grow from $50bn in 2007 to $76bn in 2012. As with any manufacturing sector, Asia is becoming a major powerhouse in PCB manufacturing with a concomitant price pressure and a decline in US and European manufacturing. Surviving and even growing as a PCB manufacturer in the UK is therefore by no means a mean feat.

Looking at the actual methodology, it comes as a surprise to find that the concept of a printed circuit board was already apparent to Edison when he responded to the Sprague Electrical Company request on how to "draw" conductive traces on paper. Early methods were "additive", in that they suggested different ways of adding a circuit to a substrate. In 1913, Arthur Berry filed for a patent for etching away metal covered in a pattern of resistant material to leave defined tracts, forming the basis for so called "subtractive" methods. These evolved, invention by invention, until by the end of World War II in the UK, the founding father of modern PCBs, Paul Eisler, was electrodepositing copper foil on planar substrates and etching it away with ferric chloride to leave circuits .

By 1948, the US had released the technology for general application and the technology has expanded from there. Nowadays, PCB manufacturers can purchase boards with a surface bonded copper sheet layer, itself covered in a photoresist layer, ready for PCB production.

Initially all added components were fixed to PCBs by wires going through the board (Through-hole mounting), a method still used for larger components; with the 1960s came the surface mounting with soldering (Surface mount).

Even with innovations, this is a well established technology, with an apparently straightforward manufacturing process, that lends itself to mass production of low cost units. So how can a UK PCB company remain competitive?

Cue my visit to Anglia Circuits Limited, camera in hand, with a brief to photograph staff, to capture the key stages in the PCB work-flow at the company and to photograph examples from the wide range of PCBs produced to date.

The visit

After a warm welcome by Matthew Kember, Owner/Manager of Anglia Circuits Limited, and an introduction to the other team members, the staff photos came first. Whilst most people do not like their photos being taken, I was treated courteously and gained an impression of a friendly, positive, dedicated team and a well run company from the conversations I had. This impression was reinforced as I toured the company to photograph the key stages in PCB manufacturing at Anglia Circuits Limited and met more staff on the shop floor.

Factor 1. Targeting a niche market

Anglia Circuits Limited specialises in short production runs of tens to hundreds of PCB made to order for a clients specialist requirements. This distinguishes them on the one hand from the other specialists who make unique one off PCBs, which are used in prototype testing or R&D, and from the mass market that produces thousands to millions of a particular PCB design. This targeting of a niche market for short production run PCBs is the first factor contributing to the company's success.

Factor 2. Setting high quality standards

Quality control was a consistent theme when I began my photographic tour of Anglia Circuits Limited, (reproduced in a truncated version as a photo album at http://picasaweb.google.com/miltoncontact/PCBManufacturingAtAngliaCircuits to complement this article and as thumbnail links in this document). A very simplified description of the PCB production nevertheless gives a good impression of the checks at every stage.

Circuit plans arrive from clients and are screened by resident expert before being printed as acetate masks (slide 02) for the photo-lithographic etching process. A completed PCB may consist of up to 14 separate layers of circuits fused in a completed board; each layer requires its own design. The acetates are then visually inspected (slide 03) before being passed on for alignment and mounting on the PCB/Copper/Photoresist blank board (slide 04). Once exposed, (slide 05), the unmasked resist is removed, exposing bare copper (slide 06) which is etched away to leave the remaining tracks under their layer of protective tin resist (slide 07). The tin layer is itself removed, revealing the copper circuits beneath (slide 08). At this point, each layer produced is checked by a sophisticated computer with image analysis software: Any highlighted potential defects are assessed by the human operator, who can remedy minor errors (slide 09).

The individual circuit layers are then accurately assembled by hand (slide 10) and heat bonded. The multi-layer PCB is precision drilled to permit through board mounting of future components (slide 11) and the holes themselves are carbon coated and plated to ensure electrical conduction where required between layers (slide 12). The drilled boards need to go through a final stage of photolithography to produce the surface circuits of the stack (repeat of slides 03 - 09).

The boards are sprayed with a protective coat that imparts the characteristic green (or any other) colour for a PCB (slide 13). Yet another photolithographic process is used to expose the solder points on the board (slide 14). These points are treated to impart the final silver or gold finish (slide 15).

The final stages are to print the text descriptions on the board (slides 16 and 17) and cut out the individual PCBs from the larger multi-unit panels (slide 18). The completed PCBs are then inspected manually for accuracy and surface defects (slide 19) before testing every individual circuit on each PCB using a state of the art EMMA flying probe (slide 20).

So you can see, even from this simplified description, that the continual quality control throughout manufacture ensures that the despatched product (slide 21) matches the client’s requirements by providing a high quality, tested and reliable PCBs.

Factor 3. Good relationship marketing

Matthew Kember told me that he'd asked clients what was important for them when considering Anglia Circuits Limited as a PCB supplier in a competitive market. He was surprised to hear that it was in part because the company was a family owned business established since 1968. (In fact, Anglia Circuits Limited claim to be the oldest, established PCB firm in the UK!) The company has acquired a reputation for quality, reliability and flexibility that ensured clients returned to provide more business. The positive atmosphere, ethos and practice existing within the organisation that I had noticed during my visit (and confirmed subsequently) had also been applied externally to foster good relations with clients.

The continued nurturing of clients and meeting their needs with a quality service has meant that 90% of the business derives from existing and established customers who return year after year.

Conclusion

By targeting a particular niche in the market for PCBs - low volume production, Anglia Circuits Limited is able to concentrate on the provision of a high quality controlled product to discerning clients who, through good relationship marketing, have formed a loyal client base providing 90% of the business. The result is that Anglia Circuits Limited was able to expand by 25% two years ago, acquire more state of the art equipment to complement and improve their existing production lines this year. They are considering another expansion phase in the near future; All this in a highly competitive and saturated World market.

You can contact Matthew Kember for more information about Anglia Circuits Limited and their PCB manufacturing on 01480 467770.

Author: Dr Chris Thomas, Director Milton Contact Limited

Creating effective communication in your team, your business or internationally, through interpersonal skills, text and images.

A PDF version of this document with 21 images is available at http://www.miltoncontact.com/news01/PCB-manufacturer.pdf

Friday, 15 February 2008

Suffolk eyes Life Science Opportunities

In the wake of the Sainsbury Review suggesting a greater regional activity in the UK’s life sciences sector, Dr. Carol Rowntree of St Edmundsbury Economic Development Services invited representatives of Suffolk local authorities and interested parties from Suffolk and Cambridge to attend a meeting hosted at Genzyme’s Haverhill plant on the 6th February, 2008. The aim was to give an introduction to Life Sciences in the East of England and learn more about a long standing and successful business in this sector.

The attendees were (alphabetical, not in order on photo!):

Dr. Belinda Clarke, ERBI (speaker)

Steve Clarke, Business Link

Emma Cooney, Forest Heath DC

Simon Cousins, VP and General Manager, Genzyme, Haverhill (Host & Speaker)

Dawn Easter, Mid Suffolk DC

Vimmi Hayes, SDA

Neil Henry, Babergh District Council

Andrea Mayley, St Edmundsbury BC

Gail McAndie, SCC

Hendrik Pavel, St John’s Innovation Centre

Kirsty Pitwood, St Edmundsbury BC

Jai Raithatha, SCC

Chris Rand, St Edmundsbury BC

Nicola Rogers, EEI

Carol Rowntree, St Edmundsbury BC

Louise Rushworth, GCP

Vijay Sundram, Ipswich BC

Dr. Chris Thomas, Milton Contact Ltd

Dr Belinda Clarke of ERBI gave an impressively jargon free presentation on the UK’s high 2nd place ranking in the world in terms of biotech companies, attracting 27% of Pharma investment and accounting for nearly a quarter of the worlds top medical devices. Pharma exports are valued at $21.3bn and the industry is a major employer. The East of England accounts for a significant proportion of this activity.

Whilst still very Cambridge centric, small companies are at the start of a progression from start-up venture-capital funded R&D in bio-incubators. They generate value products that end with their high profile acquisition by larger players in multimillion pound deals. Recent examples included CAT sold to Astra Zeneca for £702m and Domantis to GSK for £230m.

The recommended shift in regional investment is to support the four pillars of Life Sciences, Access to Finance, International Profile, Skills & Training, and partnering. This is to be achieved through an increased focus on science parks with a major emphasis on capital expenditure.

With the audience now appreciative of the importance of the Sector, Dr Simon Cousins, General Manager of the Genzyme plant at Haverhill, described the successful growth and investment at the site, which overlooks the town of Haverhill nestling in the valley below.

Genzyme has grown as an international company from its first beginnings 27 years ago by specialising in niche pharmaceutical production for high value (if low patient number) medical conditions. These ranged from Hyaluronic acid polymer sheets for bio-surgery, via diagnostics to the treatment of genetics ailments such as Gaucher’s Disease.

The Haverhill site was originally involved in chemical reagent manufacturing, until the parent company initiated a transformation into the company’s major distribution outlet and developed modern continuous flow manufacturing of Genzyme’s first flagship product Cerezyme. With a 25 year history at Haverhill, Genzyme, with its 300 plus staff, has build up good relations with the local community and authorities and benefits from close proximity to Stansted Airport.

The event culminated in a tour where Simon’s enthusiasm brought to life the tremendous achievements of reliable and consistent, high quality bulk pharmaceutical production in the absence of dangerous solvents. Modern plant design also ensured energy and resource recycling, relevant in these times of increasing environmental awareness and rising energy costs.

With the impressed delegates having a better basic understanding of the principles underlying the Life Sciences sector, the future challenge must surely be – how to ensure that Suffolk becomes bio-country.

The attendees were (alphabetical, not in order on photo!):

Dr. Belinda Clarke, ERBI (speaker)

Steve Clarke, Business Link

Emma Cooney, Forest Heath DC

Simon Cousins, VP and General Manager, Genzyme, Haverhill (Host & Speaker)

Dawn Easter, Mid Suffolk DC

Vimmi Hayes, SDA

Neil Henry, Babergh District Council

Andrea Mayley, St Edmundsbury BC

Gail McAndie, SCC

Hendrik Pavel, St John’s Innovation Centre

Kirsty Pitwood, St Edmundsbury BC

Jai Raithatha, SCC

Chris Rand, St Edmundsbury BC

Nicola Rogers, EEI

Carol Rowntree, St Edmundsbury BC

Louise Rushworth, GCP

Vijay Sundram, Ipswich BC

Dr. Chris Thomas, Milton Contact Ltd

Dr Belinda Clarke of ERBI gave an impressively jargon free presentation on the UK’s high 2nd place ranking in the world in terms of biotech companies, attracting 27% of Pharma investment and accounting for nearly a quarter of the worlds top medical devices. Pharma exports are valued at $21.3bn and the industry is a major employer. The East of England accounts for a significant proportion of this activity.

Whilst still very Cambridge centric, small companies are at the start of a progression from start-up venture-capital funded R&D in bio-incubators. They generate value products that end with their high profile acquisition by larger players in multimillion pound deals. Recent examples included CAT sold to Astra Zeneca for £702m and Domantis to GSK for £230m.

The recommended shift in regional investment is to support the four pillars of Life Sciences, Access to Finance, International Profile, Skills & Training, and partnering. This is to be achieved through an increased focus on science parks with a major emphasis on capital expenditure.

With the audience now appreciative of the importance of the Sector, Dr Simon Cousins, General Manager of the Genzyme plant at Haverhill, described the successful growth and investment at the site, which overlooks the town of Haverhill nestling in the valley below.

Genzyme has grown as an international company from its first beginnings 27 years ago by specialising in niche pharmaceutical production for high value (if low patient number) medical conditions. These ranged from Hyaluronic acid polymer sheets for bio-surgery, via diagnostics to the treatment of genetics ailments such as Gaucher’s Disease.

The Haverhill site was originally involved in chemical reagent manufacturing, until the parent company initiated a transformation into the company’s major distribution outlet and developed modern continuous flow manufacturing of Genzyme’s first flagship product Cerezyme. With a 25 year history at Haverhill, Genzyme, with its 300 plus staff, has build up good relations with the local community and authorities and benefits from close proximity to Stansted Airport.

The event culminated in a tour where Simon’s enthusiasm brought to life the tremendous achievements of reliable and consistent, high quality bulk pharmaceutical production in the absence of dangerous solvents. Modern plant design also ensured energy and resource recycling, relevant in these times of increasing environmental awareness and rising energy costs.

With the impressed delegates having a better basic understanding of the principles underlying the Life Sciences sector, the future challenge must surely be – how to ensure that Suffolk becomes bio-country.

Sunday, 20 January 2008

Promoting your business with text and images - Overview

As a Director or Marketing Manager of a small/medium sized business, you need to communicate with your existing and future customers. Text and images still form a significant part of the tool kit you will use.

My new e-book, "How small businesses can use text, images and design to promote their companies" will give you a practical overview of the key resources you can use. There will inevitably be omissions so your comments and input will also be valued.

The book is based on my practical experience as a company director, providing copy and design for clients and my own company.

I have also gained valuable insights and different perspectives through Networking and collaborating with others.

Our communication needs are summarised by the graphic below. There are four levels at which we can interact with our customers and peers.

Level 1 is the core of our businesses - our direct and immediate interaction with the existing and future clients.

Level 1 is the core of our businesses - our direct and immediate interaction with the existing and future clients.

The tools here start with our business card and website - the first most likely reference points people will find and check us out by. We maintain a recognisable brand or image via our correspondence, logo and product design.

Level 2 represents direct advertising through the media, leaflets, brochures, posters, viral marketing and exhibitions. Often this is done for new products or offers.

Level 3 is where we support the image of our company as a trusted expert, through articles, news, information and even books. Rather than bluntly advertising, the display and sharing of our knowledge creates a desire to want to work with us.

Level 4 are the smaller reminders of our companies existence; e.g. the company calendar, promotional pen or memory stick.

Future articles will expand both on the levels, the means and the toolkit!

You can subscribe to my e-mail distribution of new articles using the simple form at the bottom of my page at http://www.miltoncontact.com/art-photography.html

My new e-book, "How small businesses can use text, images and design to promote their companies" will give you a practical overview of the key resources you can use. There will inevitably be omissions so your comments and input will also be valued.

The book is based on my practical experience as a company director, providing copy and design for clients and my own company.

I have also gained valuable insights and different perspectives through Networking and collaborating with others.

Our communication needs are summarised by the graphic below. There are four levels at which we can interact with our customers and peers.

Level 1 is the core of our businesses - our direct and immediate interaction with the existing and future clients.

Level 1 is the core of our businesses - our direct and immediate interaction with the existing and future clients.The tools here start with our business card and website - the first most likely reference points people will find and check us out by. We maintain a recognisable brand or image via our correspondence, logo and product design.

Level 2 represents direct advertising through the media, leaflets, brochures, posters, viral marketing and exhibitions. Often this is done for new products or offers.

Level 3 is where we support the image of our company as a trusted expert, through articles, news, information and even books. Rather than bluntly advertising, the display and sharing of our knowledge creates a desire to want to work with us.

Level 4 are the smaller reminders of our companies existence; e.g. the company calendar, promotional pen or memory stick.

Future articles will expand both on the levels, the means and the toolkit!

You can subscribe to my e-mail distribution of new articles using the simple form at the bottom of my page at http://www.miltoncontact.com/art-photography.html

Subscribe to:

Posts (Atom)